A Green Brand Finding Roots in Sustainability

Saloni Doshi

A Green Brand Finding Roots in Sustainability

Get The Print Version

Tired of scrolling? Download a PDF version for easier offline reading and sharing with coworkers.

A link to download the PDF will arrive in your inbox shortly.

When I became CEO of EcoEnclose, I knew I wanted to change what packaging means for ecommerce so that it becomes something businesses can be proud of.

I’m often asked how I found my roots in sustainability.

Professionally, my background spans from management consulting, large-to-small businesses, and sustainability — largely in food and agriculture. I ran a sustainable venture for several years after attending business school.

Throughout the thread of my career, I’ve focused on three primary things:

Social justice,

Environmental sustainability, and

Supporting businesses to thrive.

My husband and I took over EcoEnclose in 2015 with the intention of turning it into a large business. It was just an awesome opportunity for us.

Right from the get-go, I had the vision of EcoEnclose as an incubator of sustainable packaging innovation.

Our commitment to sustainability has continued with the launch of dozens of new packaging solutions. With each of them, we have approached research and development in such a way that we can be confident they truly are the most ecological option in their category.

Let me walk you through my logic behind becoming a staple of sustainability, and what that means for consumers.

Becoming a Cornerstone of Eco-friendly Ecommerce

At the time of our launch, ecommerce was gaining momentum. We wanted to take a prescriptive approach — where we’ve designed, developed, or sourced the most eco-friendly option in each packaging category.

The ultimate goal was for customers to come to us, tell them what their sustainability values are, and allow us to point them in the right direction.

With that lens, we brought on a bunch of different products.

We started with a conundrum that was facing eco-minded apparel companies: if I’ve made clothes that represent my ethics and sustainable values, how can I ship them in a standard poly mailer. This led to the multi-year development of a 100% recycled and recyclable poly mailer.

We then moved to 100% recycled boxes, as this was during the height of the subscription model boom.

We wanted to have an offering that allowed people to have 100% recycled boxes, but also boxes that were custom cut for their needs (and ensure they did not have to ship any excess air), and also printable. We invested in the ability to custom print at fairly low volumes as well.

And then we brought on a line of different paper mailers, all of which are 100% recycled, easy to recycle, that each address different functionality that a product might need in packaging.

We also added the little things: shipping labels, tape, etc. We wanted to create a top-to-bottom sustainable practice.

Defining the Conscious Customer

We work with several types of customers.

The first is one who is used to their existing packaging but wants to up their sustainability game and isn’t sure where to start. That is where educational content comes in. For them, the problem we’re solving is cutting through all the clutter, vagueness, and uncertainty in the world of sustainability and packaging, and being a voice of research and reason as they make those decisions.

Then there are other customers that really want a branded packaging experience, and maybe they’ve been able to find something sustainable that they feel good about, but they haven’t been able to find an ability to brand their packaging at the volumes that make sense to them. Our minimum order quantity is fairly low, and we’re also a pretty high touch provider. So, if somebody has a small shop and they want to get their packaging printed, they sometimes don’t have a designer to help them. We’re really helping them through the process of getting beautiful packaging.

In addition, we have customers who want to or already have moved to sustainable packaging but are nervous about losing functionality — damaged products, broken mailers, you name it.

We support them in that journey by offering a really generous sample kit of every single thing we offer — so they can test and ship things and see if it works.

We also often work with companies who aren’t interested in any specific one of our packaging solutions, but instead want to custom create a unique and eco-friendly solution for their product set. With these customers, we do the work of designing, R&D and prototype iteration.

In fact, this process has led us to create many products directly in response to customer feedback or requests. We’ve designed and released five or six products in the last 18 months alone specifically in response to customers that have said, “listen, I moved to sustainable packaging and I lost functionality” or “I want sustainable packaging but I don’t like anything on the market today.”

We’re really on the ready to evolve our offerings when we find that functionality isn’t there and what people want.

Customer motivations behind sustainability

Some brands are deeply passionate about sustainability — it is evident through their product development and marketing – and they want to echo that throughout their fulfillment process. This is our core niche customer that we started serving years ago. Either there is an advocate in the company — like a new fulfillment arm, or a brand and marketing hire who looks around and is displeased by the amount of packaging and waste the company produces.

Sometimes, the push comes from customers. There are a lot of passive consumers who don’t care about packaging, but there are also an increasing amount of customers who are going to websites, learning about the origin story, and making a concerted effort to support these really passionate, independent, sustainable entrepreneurs.

Customers don’t necessarily demand sustainable packaging, but when they see efforts made towards sustainable packaging, they seem to really take notice. They’re more likely to post these packages on social media, leave a positive review, and share with their like-minded friends. Other brands see that — and realize that they need to follow suit.

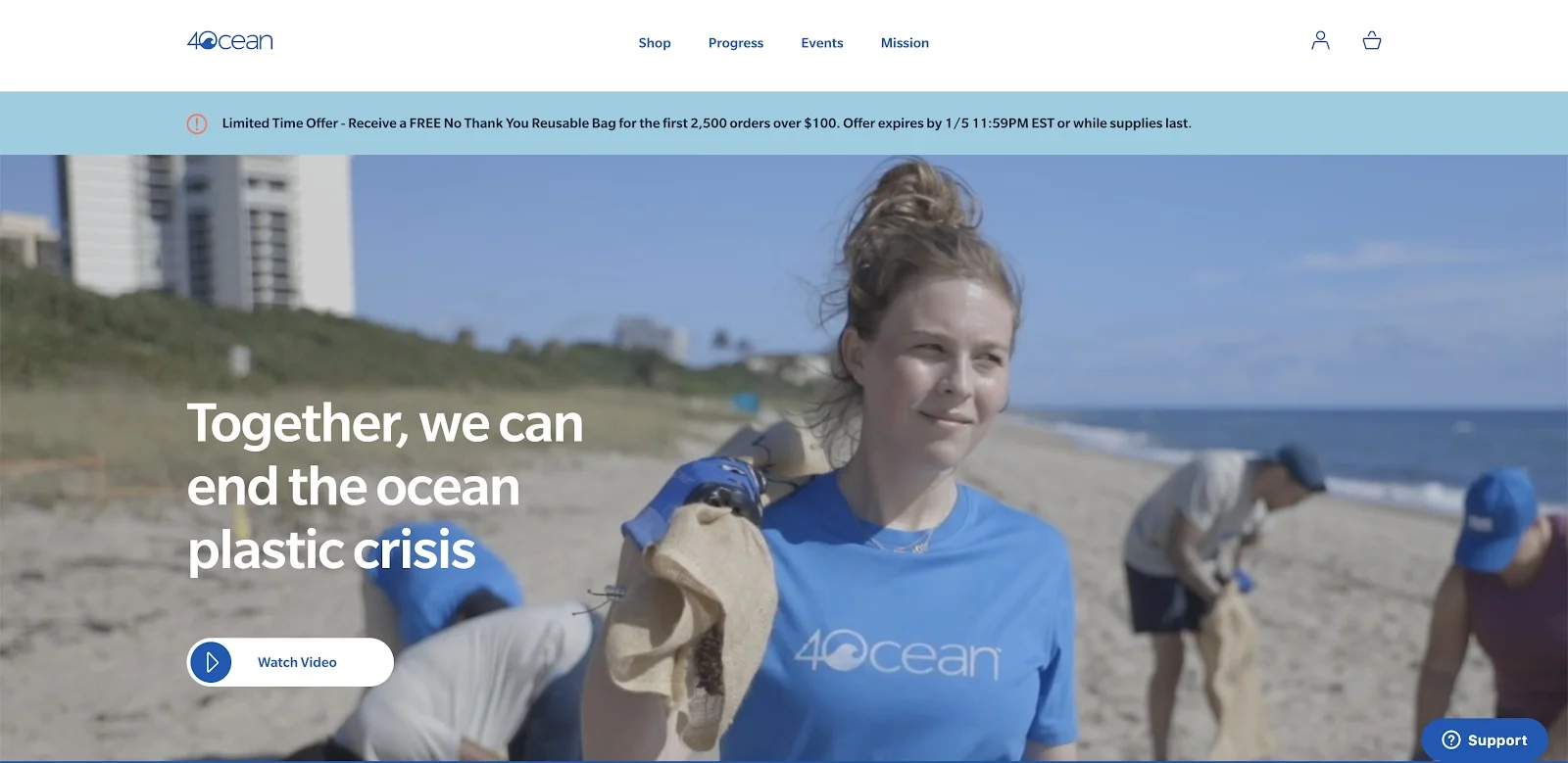

Case study: An EcoEnclose and BigCommerce Brand

4Ocean

4Ocean was founded with the purpose to remove plastic waste from oceans and waterways of the world. By matching every purchase of a bracelet (made from recycled and recovered plastics) with the removal of a pound of plastic from waterways, their business structure is designed to be disruptive in a net positive way. When 4Ocean expanded their product offering to apparel, stickers, and alternatives to single-use products, they turned to EcoEnclose to help design and create custom mailers for their launch. Today, 4Ocean uses EcoEnclose’s 100% Recycled Paper Apparel Mailers to share their products and mission with customers and ocean-lovers all over the world.

Going Green is Not Easy — Beware of Silver Bullets / Quick Fixes

The global movement towards sustainability in ecommerce is wonderful, but not without its flaws.

Bioplastics

Companies sometimes make a public declaration that they’re going to go “plastic free” — and then quickly realize there is a lot of functionality to plastic that you just can’t get from other material.

It’s really thin, it’s lightweight, it’s moisture-proof, it’s flexible. All of this stuff you just can’t get out of a paper and natural fiber.

So then, they turn to bioplastic (or other forms of compostable plastic).

In some merchant’s minds, using a bioplastic makes them a plastic-free company.

I’ve spent countless hours researching and going to workshops about bioplastics and compostable synthetics. I feel really strongly right now that the common bioplastic or compostable plastic options available today, such as PLA or oxo-biodegradable plastic, should not be considered “plastic-free” as they carry many of the same environmental issues that come along with plastic.

If you’re a company trying to go plastic free, it is important to remember that bioplastic brings with it so many of the challenges you are trying to avoid. The corn that goes into it deeply depletes our water and soils. PLA pollutes the ocean. It doesn’t biodegrade in the ocean orin a landfill. And PLA isn’t what you want going into the soil, so while it may technically be industrially compostable it doesn’t enrich our soil at all.

The transition to sustainable packaging is a really tough one. Companies have to consider things like cost, storage space, functionality and damages, aesthetics and so much more. Recognize that the journey will take time and that there isn’t going to be a simple, silver bullet solution.

Transit issues

If you go from a poly mailer to a paper mailer, you may have some issues with transit that you didn’t have before. You might have like one to 2% of your mailers might tear in transit. You might have a couple of damage claims that you didn’t have before.

Those are very real consequences of moving from one material to the other. And I think there are some brands that are very willing to accept those consequences because they know that their customers are willing to, because the impact is so important.

But for some brands that’s a huge issue. Each brand needs to determine how to balance their sustainability values with their packaging, and how much testing and experimenting they are willing and able to take on.

Commitments outside of packaging

If you make a commitment to remove materials from your entire operation — think about it. Everything from your hang tags to your poly bags to your shipping labels to your inner protection. There are so many aspects to shipping supplies that I think people can quickly feel overwhelmed and maybe a little bit discouraged. I’m hopeful that if somebody came to us, they would feel like they have a real partner in that journey, but if they don’t, if they tried to do it on their own, it is a very overwhelming task.

Rising return rates and the holiday season

In a brick and mortar retail environment, around 8-11% of purchases are returned. Even when people can touch and feel and see things, they still have a significant return rate.

In ecommerce, the return rate is quadruple that. People sometimes purchase 10 items with the intention of returning eight. But if ecommerce stores cut back on their return policy, they won’t see the conversion rates that they want.

It is a double-edged sword: even sustainability-minded customers still want to be able to return things, because if they get something and can’t use it, it is still more sustainable to return the item and have it re-sold to someone who will use it, than for me to do nothing with it and let it waste away.

At the same time, returns are becoming an operational and cost nightmare for brands. From a sustainability standpoint, every time your customer returns an item you’re doubling that shipping footprint.

I think building returnability into your website in such a way that both allows for a seamless user experience and allows for products to be returned in their original packaging can go a long way.

The impact of buy online, pickup in store (BOPIS)

There are a lot of merits to a strategy that allows customers to purchase an item online and then opt to return it in store. But — there’s also a lot of raging debate over just how eco-friendly it is to online shop versus hop in your car and drive to the store. So much of it depends on the distance between you and the store, as well as your order quantity. There are a lot of variables that make it hard to determine.

But I think the one thing that experts seem to agree on is that the buy online and pick up from the store is oftentimes, the most unsustainable way that you can shop. Because especially in those instances where you’re buying online and then if they’re shipping the product to the store because then you’re doubling your eco footprint.

Think about it — you’re:

Using electricity on your computer,

Taking fulfillment and shipping resources from the store, and then

Getting in your car and driving to the store, where someone had to put the product on a truck to get it to the store for you to pick up.

In addition, stores have different packaging between their online and offline businesses. (Think poly mailers versus large retail bags.)

Can you use sustainable packaging in a 3PL?

It’s possible — and more and more brands are doing it. When EcoEnclose works with a fulfillment center, it is usually when one of our large customers moves into a fulfillment model and wants to use EcoEnclose.

In the same thread, there are an increasing amount of brands we’ve spoken with that are frustrated because their 3PL won’t adhere to their sustainability requests. I think in 2020 we’ll find an emerging set of 3PLs that make sustainability their differentiation.

How to become a sustainable brand 101

In the rising direct-to-consumer industry, many companies have the ability to make changes pretty quickly to their products, marketing, and fulfillment. There are some easy steps you can take to start incorporating sustainability into your brand in a manner of weeks.

1. Look at your product and how it’s constructed.

Look at your product itself. Use this checklist for guidance.

Have you designed a product that intends to be durable and last a long time?

Have you thought through what materials you’re sourcing from to create that product and what can you do to be better?

Can you incorporate recycled content, especially post-consumer waste, in the manufacturing of your product?

Do you know the right resources and responsible harvesting of resources?

Is it happening for the raw materials of your product?

A lot of times we’re seven steps removed from the products or materials that end up coming to us. Simply tracking and understanding the supply chain can open your eyes to all the ways you can make small or large changes. It could be by starting to source FSC certified wood at the very least, or I’m going to source organic cotton instead of this regular cotton.

2. Do a cost-benefit analysis.

Any large business decision, especially if you’re a premium brand, should come with a cost-benefit analysis. As more and more emphasis is placed on the customer’s opinion, some of those decisions can pretty easily lead to a price change that makes the cost worthwhile or that covers the increased cost.

If you’re starting to green your product, you also want to be proud of how you ship and have the way that you ship reflect your initiative in overall sustainability.

3. Think about your packaging strategy.

Are you going to ship in a box? Or in a mailer? And if you’re going to ship in a mailer, does it need to be a poly mailer or can it be a paper mailer?

And once you make those decisions, think about how you can get as much recycled content and post-consumer waste in that package as possible.

If every ecommerce package was made with 100% recycled, 100% consumer waste, that would be such a boom to the overall recycling industry, and would create such a market for recycled content that would then drive so many solutions that are currently plaguing our waste management and recycling supply chain.

4. Focus on the smaller things.

Can you switch from a polybag to a paper option or void fill?

Can you use recycled content?

Can you do less and reduce the amount of material you’re using?

Can you go to recycle-friendly tape and recycled tape?

5. Look across your entire organization.

How well are you managing waste in your own operations?

Are you responsibly recycling batteries?

Can you partner with TerraCycle to recycle snack wrappers?

Once you start on a sustainability journey, you start to notice waste and hard-to-recycle things. Start to tackle them one by one. You won’t be able to do everything by tomorrow — so think about it as a sequence.

Ecommerce sustainability resources

Sustainable Packaging Coalition

Outdoor Retailer conferences and content

Saloni is the CEO and Chief Eco Geek at EcoEnclose, a leading provider of sustainable shipping solutions for ecommerce brands. She is passionate about helping conscious companies launch, grow, and thrive. In the last three years, EcoEnclose has helped over 20,000 companies ship their products in ways that strengthen their brand and support the planet.